2017 Acura NSX vs 1990-2005 Acura NSX

Acura Press Release Highlights

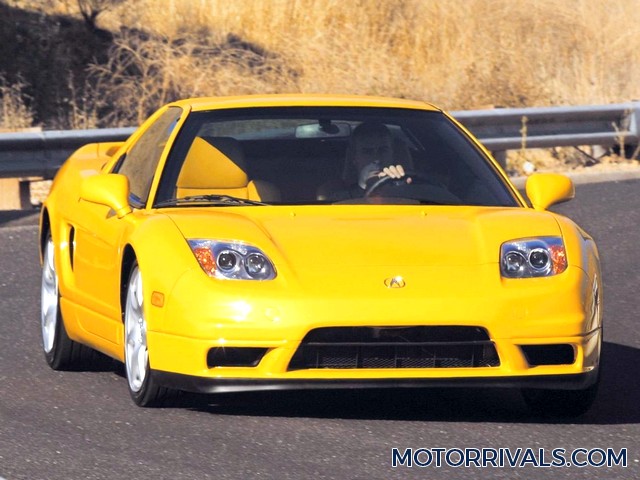

The Acura NSX was created to revolutionize supercar performance,

delivering a more vivid, immediate and intuitive dynamic experience with

instant acceleration, ultra-powerful yet easily controlled brakes, and

exceptional handling—making the most of the driver's capabilities in

every type of driving environment and rewarding the most skillful

drivers with its extraordinary at-the-limit dynamic capabilities.

Like the original Acura NSX—the world's first all-aluminum supercar—the all-new NSX has a cutting-edge structure: its multi-material body and space frame utilize new materials and construction methods to create a structure with unprecedented dynamic rigidity.

The new Acura NSX "advanced sports package" is a design philosophy that seeks to optimize the design and packaging of all major vehicle systems—the body, chassis, interior, Sport Hybrid power unit (engine, Direct Drive Motor and 9DCT) and key hybrid components including the Intelligent Power Unit (containing the lithium-ion battery pack), PDU and the TMU—to lower and center the mass of the vehicle for optimal handling and dynamic response. The new NSX has the lowest center of gravity (CG) among its core competitors.

The low CG and centered mass pay dividends in handling and response. Biasing the mass toward the center of the NSX reduces the polar moment, making the car respond (yaw rate) faster to steering inputs and reducing its rotational kinetic energy. In other words, it's easier to initiate a turn, and easier to stop the rotation. The low CG also reduces the dynamic load transfer, thus stabilizing the vertical load on the tires.

The payoffs are quick and precise response to driver inputs, minimal unwanted body movement, and stable tire grip—thus raising the performance levels.

The Acura NSX's front double wishbone and rear multi-link suspension systems were designed to support the extreme dynamic needs of this unique supercar, and work in perfect harmony with SH-AWD and all other systems.

An advanced double-joint front suspension design eliminates torque steer and steering kickback. The rear multi-link suspension provides high lateral rigidity to react faithfully to driver inputs and maintain stability.

Third-generation magnetorheological (MR) dampers continuously adjust damping forces in fractions of a second, instantaneously adapting to the driving situation, driver inputs and road conditions.

The system maintains the precise design geometry to extract the maximum grip and control from the tires. Agile at low speeds, yet supremely stable and predictable at high speeds, the NSX faithfully translates the driver's inputs and always changing road surfaces for ultimate handling performance.

Forged light alloy wheels with high lateral stiffness wrapped in 245/35ZR19 front and 305/30ZR20 rear tires provide the NSX's interface with the road. Standard high performance summer tires (Continental Conti-Sport Contact) provide excellent dry and wet weather handling and traction. The combination was tuned extensively in a joint effort with Continental to work in unison with the NSX chassis and SH-AWD systems to offer superior traction and grip.

Track-focused ultra-high performance summer tires, with elevated grip levels and even higher response characteristics are available as a dealer installed options.

The Acura NSX employs a sophisticated dual-pinion (with rack-mounted assist motor) electric power steering (EPS) system with a variable gear ratio. When on center, the ratio is tuned for optimal high speed control and stability. Off center, the gear ratio becomes progressively quicker for improved turn-in and maneuverability at low and mid speeds. The overall quick ratio effectively eliminates the need for driver's hand-over-hand steering inputs.

High mounting and component stiffness minimize lost motion to help realize high steering accuracy and faithful road feedback. Steering assist levels are modified with the Integrated Dynamics System in concert with the MR dampers to provide appropriate effort and road feel for the desired level of performance.

NSX's body shape was effectively designed to minimize aerodynamic drag while creating specifically balanced front-to-rear downforce through a total airflow management approach that focuses on utilizing airflow through each vent, while extracting maximum energy from the airflow field to cool the brakes and power unit.

Extensive research and development revealed that placing approximately three times as much downforce at the rear of the vehicle relative to the front of the car provides the optimal downforce balance for high-performance driving as well as everyday functionality.

Sport Hybrid SH-AWD is a further evolution of Acura's highly regarded Super-Handling All-Wheel Drive (SH-AWD) system in vehicles like the Acura TLX sports sedan and MDX sport-utility vehicle. This pinnacle new system electrifies the torque vectoring ability and provides this capacity to all drivers in all driving conditions.

The NSX's revolutionary Sport Hybrid SH-AWD uses torque vectoring-enhanced vehicle dynamics—and specifically direct yaw control—to ultimate advantage by utilizing the instantaneous and "always-on" capacities of its electric motors to directly create a yaw moment at any speed, under power, and in off-throttle driving maneuvers—with greater immediacy and precision.

Supported by the advanced yaw-control capabilities of Sport Hybrid SH-AWD, the NSX driver is able to execute super-precise line tracing when aiming for the apex out on the track or on a favorite winding road. What's more, the driver can do so with superb vehicle stability as well as a low workload, thus expanding the capabilities of all drivers, ranging from novice clubman to professional racer in virtually any driving scenario.

When accelerating the system provides instantaneous torque response via its three electric motors—the Direct Drive Motor and front Twin Motor Unit.

While braking, the Acura NSX employs both its muscular mechanical braking system and its regenerative braking capabilities to deliver powerful, precise and virtually fade-free brake performance with very natural and progressive pedal feel while also recapturing kinetic energy to charge the system's lithium-ion hybrid battery.

When cornering, the NSX's Twin Motor Unit and Vehicle Stability Assist (VSA) work cooperatively to enhance cornering precision (line traceability). If desired, VSA can be disabled by simply selecting the Track mode setting of the Integrated Dynamics System, and then holding the VSA "Off" button, located on a panel to the left of the steering wheel, for at least six seconds.

By taking advantage of the immediate high-torque response of the system's three electric motors to heighten control, the Acura NSX Sport Hybrid SH-AWD system elevates any driver's confidence and performance driving capabilities while extracting more performance from the car than is possible with conventional methods.

At the heart of any supercar lies a powerful and responsive powertrain. The 2017 NSX raises the game by making its tremendous power instantly accessible and finely controllable.

Primary power is supplied by the twin-turbo 3.5-liter V6 engine, with peak engine output of 500 hp and 406 lb.-ft. of torque at the driver's disposal. Broad power and torque bands mean that this massive motive force is available when the driver really wants it. Dual electric waste gates help manage boost regulation for smooth throttle transitions.

The new Acura NSX's 9-speed dual clutch transmission also plays a crucial role. Lightning-fast up and downshifts delivered seamlessly make the NSX a joy to drive—the faster the better. The wide total ratio range coupled with closely spaced individual ratios supports maximum extraction of the twin-turbo V6 power. And the transmission programming selects the right gear at the right time, or lets drivers select as they wish.

But the real secret to the NSX's virtually zero-delay acceleration lies in the seamless integration of the instant and substantial torque from the front TMU and Direct Drive Motor. This right now electric power pushes the NSX's total output to 573 hp and allows fine adjustment of power for maximum performance—on the street or track.

Importantly, the NSX's control systems manage the collective system power and torque smoothly while allowing scintillating response and acceleration. Responses can also be progressively quickened via Integrated Dynamics System settings.

For ultimate, high-G acceleration from the standstill, the Acura NSX driver can invoke Launch Mode Control. With the 9-speed DCT set in either Drive ("D") or Manual ("M") and the Integrated Dynamics System set to "Track" mode, the driver depresses the brake pedal with the left foot while simultaneously pushing the accelerator pedal all the way to the floor with the right foot. When the brake pedal is released, the NSX will perform a perfectly executed launch that utilizes peak power from the TMU, twin-turbocharged V-6 engine and Direct Drive Motor.

Seamlessly integrating both mechanical (friction) brakes with electro-servo control and a regenerative brake system, the NSX provides exceptionally precise, linear and virtually fade-free braking performance in almost any driving condition. To support the driver in high-speed driving scenarios as well as at low-speeds, the powerful brake system has been painstakingly tuned for easy, predictable modulation in any condition.

The Brembo mono block brake calipers have been designed with high rigidity to provide even pressure distribution and superior pedal feel. Ultra-high performance and lightweight carbon ceramic brake rotors are available as a factory-installed option. Both the carbon ceramic and the standard iron rotors use a two-piece floating design to maintain consistent stopping power under severe braking.

The NSX Integrated Dynamics System provides the driver with four selectable dynamic modes—Quiet, Sport, Sport+ and Track. The system integrates all of the vehicle's dynamic chassis and powertrain systems—steering, brakes, throttle, vehicle stability assist, magnetorheological dampers, engine, transmission, and Sport Hybrid SH-AWD control systems. From the available all-electric operation of Quiet mode to the closed circuit, maximum performance capacities of Track mode, the Integrated Dynamics System progressively dials up the dynamic characteristics of the vehicle based on the needs of the driver and the driving environment.

In addition to dynamic system variations, the Integrated Dynamics System varies cabin sounds via Active Exhaust Valve and Intake Sound Control to fine-tune sound quality and volume to match the dynamic character of the vehicle in Quiet, Sport, Sport+ and Track modes. Notably, there is a full 25 dB sound level difference between Quiet and Track modes—a tremendous variance in audible sensation.

The NSX Integrated Dynamics System also has the world's first custom setting menu that allows the driver to configure the vehicle's mode for startup. For example, drivers can program the car to always start in Quiet, or Sport mode, along with the ability to schedule the NSX to operate exclusively in Quiet mode during a specified time period, such as the early morning to avoid waking the neighborhood.

Integrated Dynamics System mode characteristics:

• Quiet Mode - Quiet mode prioritizes electric-only driving at lower speeds, maximizing energy efficiency and minimizing both cabin and exterior noise. The vehicle uses the TMU for initial launch from a standstill. When power demand requires the engine, it starts more quietly than in other modes and maximum engine speed is limited to 4,000 rpm, while the Active Exhaust and Intake Sound Control valves are closed for a more hushed operation. The transmission shift map also prioritizes lower engine speeds. The driver interface (tachometer and center console information display screen) features a cool and quiet blue color.

• Sport Mode - Sport mode takes advantage of the Sport Hybrid system to offer the driver a direct responsive vehicle or a more relaxed vehicle according to their driving inputs. Compared to Quiet Mode, it eliminates the 4,000 rpm limit on the engine and quickens throttle response. A more aggressive transmission shift map holds gears longer and allows higher rpm shift points. The Intake Sound Control system and the Active Exhaust Valve are activated, allowing additional intake and exhaust sound to permeate the cabin for a more emotional driving experience. Like Quiet mode, Sport mode provides idle stop function. The Sport mode is the default setting in normal vehicle operation.

• Sport+ Mode - Sport+ further prioritizes drivetrain response and dynamic performance with faster up- and down-shifts of the 9 DCT and still more aggressive throttle mapping. Maximum use of the electric motor torque provides more explosive acceleration. Increased agility is achieved by harmonizing a more aggressive Direct Yaw Control setting that works in concert with the magnetorheological dampers, Agile Handling Assist, and the Electric Power Steering system—perfect for a spirited drive on a winding road. It also transmits a higher degree of steering feedback, while intake and exhaust note sounds are further increased for an even more exhilarating driving experience. The TFT Meter sports an aggressive yellow "con-trail" along the tachometer needle supporting easy recognition of engine RPM. Red highlights for the center console information display also reinforce that the driver is in now in Sport+ mode.

• Track Mode

• Optimized for circuit driving, Track mode invokes the most aggressive settings and parameters to assist the driver in capturing the fastest and most consistent lap times possible, along with maximum acceleration from a standstill when utilizing Launch Mode Control. The braking system offers enhanced performance-oriented pedal feel. Up/down gearshift execution of the DCT and performance of the Super Hybrid SH-AWD and active driver aids (VSA, AHA) are programmed to support circuit limit driving, and an even greater amount of engine intake sound permeates the cabin for a heightened driving experience offering enhanced driver feedback even when wearing a helmet.

• Track mode also prioritizes the lithium-ion battery state-of-charge to maintain a consistent level of torque delivery and direct yaw moment from the three electric motors.

Of note, the VSA operation is progressively "loosened" from the Integrated Dynamics System Quiet mode up to Track mode, enabling an increasingly higher degree of freedom for the driver in exploring the dynamic capabilities of the Acura NSX. In "Track" mode, the VSA system can also be completely disabled by the driver.

To better understand the dynamic functioning of the Sport Hybrid SH-AWD powertrain and all its related systems—including the V-6 engine, Rear Direct Drive Motor, mechanical and regenerative braking systems, front-mounted Twin Motor Unit and IPU (hybrid battery).

The exterior design of the all-new 2017 Acura NSX reflects the integration of exotic supercar aesthetics and exceptional supercar performance. The "Interwoven Dynamic" overarching design theme for the exterior architecture epitomizes the concept of "form following function," as every character line, body panel shape or crease, air flow inlet/outlet, and even the vehicle's overall proportions have been designed to create a New Sports eXperience. Accordingly, each aspect of the NSX's exterior architecture has been optimized to support the dynamic capabilities of the NSX while advancing Acura design into the future.

Every square inch of the Acura NSX's exterior body panel surfaces, fluid shapes, air inlets/exhaust outlets and even the positioning/shaping/thickness of the floating C-pillars serves a distinct purpose—one that has been carefully calculated through thousands of hours of complex computational fluid dynamics (CFD) in combination with extensive wind tunnel testing in the company's advanced facilities in the United States and in Japan.

From the acutely angled slope of the chiseled aluminum hood to the rakishly shaped Acura Jewel Eye™ LED headlights and tapered front grille, the front is supercar sleek. The distinctive headlights are bisected by massive mesh-covered air inlets from below and the front fenders are highlighted by a sharply creased character line running all the way from the grille towards thinly sculpted A-pillars.

Remarkably compact overhangs, fore and aft, foretell the design and engineering team's exemplary packaging of mechanical and electrical components, while the vehicle's overall sleek yet muscular stance conveys a sense of purpose and power. The hood line, roofline, floating C-pillars and rear quarter appear as one distinctive and unified curve. The massive yet lightweight high- performance wheel and tire package fit within the arching wheel wells with minimal gap and perfect proportion.

The rear of the vehicle is equally striking, highlighted by the signature floating C-Pillars, which cascade gently from the roofline to just forward of the integrated spoiler at the trailing edge of the rear deck lid, flanking an expansive glass panel that reveals the twin-turbocharged V-6 engine.

Further accentuating the exterior architecture of the new Acura NSX are a choice of eight paint schemes, each color in the rich palette carefully selected and engineered to accentuate the exterior's bold design while ushering in a new level of paint quality within the supercar segment.

The floating C-pillars integrated into the exterior architecture of the all-new NSX are as purposeful as they are distinctive, supporting efficient body-side airflow. The C-pillars extend outward from the sloping rear roofline so that, as air flows down the sides of the vehicle, it is efficiently rerouted into the side-mounted engine air intakes. The floating C-pillars also aid engine cooling by creating a negative pressure zone around the rear heat exhaust vents, along the outside edges of the rear windscreen, improving the efficiency of hot air exhaustion. The portion of air that flows down the side of the vehicle toward the outside section of the buttress is conditioned to reduce turbulence as it passes with minimal disruption over the rear fender and spoiler.

The flush-fitting exterior door handles are both aesthetically pleasing and functional, providing a welcoming "handshake" with the driver/passenger as they extend outward from the door upon approach while at the same time supporting clean airflow along the body side.

Smart Entry with keyless access is enabled by both proximity sensors, tied to the remote key fob, and capacitive touch sensors in the exterior door handles. A proximity sensor actuates the door handles upon approach, extending them outward for easy operation. Grasping either door handle activates a capacitive touch sensor, which initiates door unlocking. Once the driver/passenger releases the handle, it returns to the flush position. The doors can also be unlocked using the remote key fob—a single push of the unlock button extends the driver's door handle and simultaneously unlocks the driver's door, while a double push of the button extends both door handles and unlocks both doors.

Upon exiting the vehicle, the driver/passenger can lock the vehicle by simply touching a button positioned just forward of the handle or by depressing the lock button on the remote key fob.

The exterior door handle mechanism is both a mechanical and electrically operated system. As is the case with an electronically operated system on a vehicle such as an EV, the driver/passenger can sometimes be locked out of the vehicle due to an onboard power failure; this is impossible with the NSX thanks to a redundant mechanical system that allows the driver/passenger to manually operate the door handle without electrical assistance. Automatic door handle extension can be disabled by a switch in the glove box for shipping or long-term storage.

The trunk is accessed by means of the remote key fob, by a button located on the driver's interior door panel, or by a button discretely located under the trailing edge of the trunk lid. In the event of a loss of power, both the driver's door and the trunk also feature a traditional key cylinder for manual locking/unlocking of the doors and trunk.

The wiper/washer system, engineered specifically for the new NSX, has been designed to operate effectively even at maximum vehicle speeds. Tested in the wind tunnel at airflow equivalent of over 180 mph, the spoiler-shaped wiper blades generate downforce on the wiper blade, while the speed-controlled wiper motor maintains a constant wiping speed, ensuring effective wiper performance in all driving conditions. Likewise, the windshield washer system utilizes a three-nozzle system for superior coverage in all conditions and driving environments, including high-speed travel.

In a further nod to improving forward visibility and providing an unobstructed view of the road, the windshield wiper arms are placed as low as possible at the base of the windshield/lower cowl section so that they remain completely out of the driver's view when not in operation. Placing the wipers below the hood also helps mitigate wind noise.

Featuring a two-tone paint scheme that accentuates the Acura NSX's low-slung look and wide stance, the door mirrors include a thin blade arm to minimize air turbulence as air flows along the side of the vehicle. This reduces local airflow noise, prevents disruption of air flowing to the side intakes, and minimizes aerodynamic drag. And like the ultra-high-strength A-pillars, the thin blade arm design improves visibility when parking and cornering. Each mirror housing includes an LED turn signal.

LED Lighting

The exterior design of the 2017 NSX features a variety of light-emitting diode (LED) lighting, including Acura Jewel Eye™ LED headlights, LED daytime running lights (DRL), and LED taillights.

Acura Jewel Eye LED headlights are a standard feature on every NSX. Designed to complement the aggressive low and wide exterior appearance, each headlight assembly contains six individual LEDs, with the four outer LEDs in operation when using the low beam setting, and all six at work when the high beams are activated.

Acura Jewel Eye LEDs provide superior down-the-road illumination with outstanding light distribution and light characteristics and a wavelength close to the human eye's luminosity curve. With their lower electrical power consumption, the NSX's Jewel Eye LED headlights also have a longer operational life compared to traditional halogen or high-intensity discharge (HID) lamps.

Utilizing the top half of each LED headlamp that makes up the Acura Jewel Eye™ LED headlight assembly are the NSX's LED daytime running lights (DRL). Located just beneath the LED headlamps are the LED position lights, composed of a series of small and tightly packed LEDs that run in a thin continuous line along the bottom of the headlight assembly. LED lighting is also used for the turn signals at both the front and rear of the vehicle.

Similar in character to the Acura Jewel Eye LED headlights at the front of the vehicle, the LED taillights have a compact and narrow appearance with a uniquely freeform shape. The LED taillight array starts off wider, toward the center portion of the rear of the vehicle, then gently tapers as it wraps around towards the outside corners/rear fender arches.

The NSX's multi-material body design concept extends throughout the entire body construction. By employing sheet molding composite (SMC), aluminum stampings and high temperature-resistant plastic in key locations of the body, the NSX design team takes advantage of each material's unique characteristics to create exterior body panels of the highest finish quality while also minimizing vehicle mass, optimizing weight distribution and center of gravity, and helping to ensure outstanding longevity and durability.

Used extensively in the construction of high-end exotic cars in key exterior componentry, SMC is a high-grade specialty glass-fiber reinforced polyester, its shape formed while heated under pressure within a compression molding. By utilizing special resins as well as high-strength fiber composite matting, Acura NSX exterior design engineers have developed SMC material for specific applications on the vehicle's exterior.

Specially engineered SMC material is used in the fender sections at all four corners. Designed to possess high structural rigidity, this unique SMC paneling makes an important contribution to optimizing the NSX's overall center of mass by minimizing weight at all four corners. The rear trunk skin is also made of lightweight SMC, with structural support provided by a stamped aluminum inner frame structure.

A special, high temperature-resistant plastic is used in the small body panel sections just below the floating C-pillars (forward of the rear fenders) due to the body panels' close proximity to the turbo intercoolers.

A rigid, structural SMC material has been developed for the NSX's trunk internal structure. This highly rigid construction allows the trunk structure to serve as a mounting point for the rear fenders and rear bumper for a sturdy and precise fit. An added benefit of the trunk compartment design is that it allows for easy removal when the vehicle is brought into an Acura dealer for service; after removing the rear fascia, the entire trunk structure can be removed for easy access to the engine room. This design also simplifies replacement of the rear section should the NSX be involved in a rear-end collision.

The Acura NSX door skins are made of sheet hydroformed aluminum. Sheet hydroforming is the ideal means to shape the one-piece aluminum panels that make up each door, as the process supports the construction of complex shapes that cannot be formed by conventional stamping techniques. Moreover, the aluminum door skins can be relatively thin and light as they are naturally supported by the inner door structure.

The hood, roof panel and the engine compartment/trunk frame are composed of high-grade stamped aluminum. A carbon fiber roof panel is optional. Like the other composite materials utilized in the exterior, the use of aluminum in these areas offers light weight with excellent structural rigidity and surface quality.

As the near final step in the vehicle assembly process at the Performance Manufacturing Center, the exterior body panels are attached to the vehicle's space frame, starting with the roof, then the doors, etc., working from the top down. This process, along with the high degree of dimensional accuracy for the underlying space frame, allows for fine adjustment of panels to achieve consistent and symmetrical panel gaps.

To support the NSX's ambitious performance targets, innovative packaging design and exotic styling, the development team completely reimagined the exterior engineering for this modern supercar so that maximum energy is extracted from the flow of air around and through the NSX with the highest efficiency. This "total airflow management" strategy supports complete power unit cooling and air intake, brake system cooling, and aerodynamic performance—drag and downforce—at a very high level.

Computational fluid dynamics (CFD) was used extensively during development to maximize the performance of the power unit cooling systems: First, for the proof-of-concept in establishing heat management strategy at the earliest development stage; and second, for continuous thermal performance improvement as the vehicle matured through development.

Along with the use of advanced CFD, wind tunnel and real-world testing, the development team employed computerized lap-time simulation models of some of the world's most legendary proving grounds that could then be run on chassis-dynamometers allowing testing and validation of computer models for thermal management.

Aerodynamic Design Highlights:

Efficient cooling openings at the front of the vehicle maximize cooling airflow across the key heat exchangers located within the front section (front engine radiators, Twin Motor Unit cooler, condenser, the transmission gear cooler, hybrid Power Distribution Unit).

Optimized front exit flow paths consider total flow, maximum downforce, low coefficient of drag, and downstream flow structure to feed the engine air intakes.

Wheel wake management vents work in conjunction with fender vents to stabilize airflow down the side of the vehicle, allowing the air to smoothly enter the signature side intakes for efficient cooling. The air that enters the side intakes is distributed to three areas: engine intake, engine room cooling, and turbo intercoolers.

Air flowing over the roof and down the rear glass is captured to feed the transmission clutch cooler and introduce engine-room cooling flow.

Airflow across the rear deck lid works in concert with the taillight slots and rear diffuser to generate significant downforce and effectively manage the air wake generated behind the vehicle. It also minimizes the low-pressure wake coming off the rear of the vehicle and therefore minimizes drag.

Optimization of front/rear downforce distribution for improved handling and stability

Rear brake cooling air ducts designed into the hollow sub-frame direct cooling air to the rear brakes using specially tuned air deflectors located on the rear suspension arms.

NSX achieves top-class aerodynamic balance and supercar aerodynamic downforce. Aerodynamic drag is minimized, even while moving large airflows through the vehicle to cool the power unit. Aerodynamic downforce is created by utilizing airflow through each vent, as the NSX "exhales," and through more traditional aerodynamic shape optimization.

The Acura NSX has undergone extensive testing at the company's state-of-the-art wind tunnel in Raymond, Ohio, using ultra-detailed 40-percent-scale models that replicate the suspension, wheel/tiire, intake and exhaust vents, heat exchangers and major under-hood components. The NSX has also been verified and further refined through testing at full scale in the company's wind tunnel in Tochigi, Japan and on real and simulated proving grounds throughout the world.

Airflow management vents and precision ducting were tuned to optimize forms with aerodynamicist and designer input during wind tunnel test sessions. A 3-to-1 downforce ratio—placing three times as much downforce at the rear as at the front of the car—provides the optimal balance for high-performance driving as well as everyday functionality.

Six vortices flow at the rear of the NSX, including those that support the highest downforce across the rear deck lid. Air flowing from below the car and exiting through carefully optimized rear diffuser fins is a critical vortex that further anchors NSX to the ground. Uniquely, the fins are not parallel to each other, but are narrower toward the front of the car and wider at the rear. This design amplifies negative pressure, enhancing diffuser efficiency which further maximizes downforce.

Of note, the NSX aerothermal team worked to evaluate thermal loading in racetrack conditions using a chassis dynamometer. In addition to simulating key performance parameters, such as engine speed and braking, the test included varying wind speeds based on real-world track data. Simulations included Sebring International Raceway and Virginia International Raceway, the latter serving as one of the primary development tracks for the new NSX.

The NSX paint team at Acura's innovative new Performance Manufacturing Center targeted the highest levels of paint quality with reduced environmental impact, consistent with their target of next-generation quality and craftsmanship.

Because the Acura NSX's exterior body panels are not attached to its space frame until the conclusion of the vehicle assembly process, body panels are treated and painted separately from the frame and are finished to an exceptional level of quality and luster by expert technicians at the Acura Performance Manufacturing Center.

NSX body panels enter the paint process attached to a specially designed fixture that locates the panels in a position and angle similar to how they are oriented once installed on the vehicle.

All body panels are covered with a high-quality primer coat and, depending upon the specific color application, then receive between five and seven coats of paint. Each layer of colored paint applied to the body panels is allowed to fully cure prior to the next application.

A high-quality/long-lasting clear coat is then applied.

To help minimize the potential for "orange peel," which occurs when the clear coat on vertical body panels is pulled down by gravity during the curing process, the body paint fixture has hinges that allow the vertically oriented body panels—doors and fenders—to be rotated to a near-fully horizontal position during the curing process.

Once cured, the panels undergo careful inspection in a newly designed inspection booth utilizing high-intensity LED lighting to help associates identify and address even the smallest irregularities.

Body panels are then hand finished after the first layer of clear coat, and again after the second clear coat.

A complementary and essential component of the all-new Acura NSX's New Sports eXperience is its driver-centered interior design, where every element—materials, shapes, technology and layout—are optimized to enhance the driving experience. Exceptional ergonomics, a hallmark of the original NSX, have been further advanced. Moreover, as a pinnacle representation of Acura Precision Crafted Performance, the NSX is designed to provide outstanding comfort, quality and advanced, intuitive technologies, all presented in clean and modern aesthetic.

Artfully sculpted and ergonomic seats are enhanced with supportive yet comfortable bolstering, firmly yet comfortably supporting the driver and passenger and clarifying the driving experience. Strategically placed console and door padding further elevate the driver and passenger lateral support. Materials such as leather and Alcantara® were carefully selected for the ideal combination of craftsmanship and dynamic driving support.

The driver's instrument cluster and center console have been designed to enhance the driving experience with intuitive layout and simple operation, creating a "simple sports interface" for the driver.

The next-generation Acura NSX interior also supports the idea of a customizable driving experience, employing a trifecta of advanced sound modulation technologies—Active Sound Control, Intake Sound Control and Active Exhaust Valve—that work in concert with the NSX's Integrated Dynamics System to deliver a tunable cabin sound experience commensurate with the desires of the driver and the driving environment.

To maximize forward visibility, the NSX employs a new technology—three-dimensionally-bent and quenched ultra-high tensile strength steel—to create highly rigid yet very thin A-pillars that offer exceptional strength and roof-crush protection while providing the vehicle's occupants with a panoramic view of the road ahead.

In addition to the tremendous visibility offered by the streamlined A-pillar construction, the heights of the instrument panel and gauge cluster hood are minimized for enhanced forward visibility.

The driver's gauge cluster and Display Audio touchscreen illuminate upon vehicle entry and progressively brighten to full strength with the start of the Power Unit. The display screen of the driver's gauge cluster presents rich and brightly colored typeface with information that is easy to read against a black background.

Additional interior lighting includes blue-tinted LED lighting for the foot wells and center console and twin LED map lights located in the overhead console.

Superbly supportive for spirited driving adventures on the road or track, while offering all-day comfort for the hours in between, the NSX sport seats were developed with exemplary ergonomics.

To maximize support and comfort, the four-way manually adjustable driver and passenger seats include tall bolsters with integrated support structures for improved lateral hold, as well as an appropriate balance of ingress/egress and freedom of shoulder movement. The Alcantara center panels in the seat bottom and seatback enhance lateral grip, while the leather outer surfaces improve ease of ingress/egress.

The seat bottom structure is composed of stamped aluminum for reduced weight. Both the seat and seatback are of sturdy construction to hold the driver/passenger in place and for longevity and crash performance considerations, and the headrest is designed to accommodate a helmet for track outings.

Seating options include four-way power-adjustable heated sport seats with 4-way power lumbar and 2-position memory (driver) in either full leather or leather with Alcantara inserts.

To facilitate ease of ingress and egress, the optional power driver's seat automatically moves rearward when the ignition is turned off.

As the centerpiece of the driver's tactile and dynamic driving experience, the NSX steering wheel has been painstakingly designed to provide a seamless connection between the car and driver, providing superior grip, comfort and control.

Steering wheel-mounted controls put critical features and functions at the driver's fingertips. On the left side are the audio volume wheel and source selection button as well as phone controls; to the right are the Multi-Information Display (MID) controls and cruise control functions.

While leather is standard, hand-wrapped carbon fiber trim for the steering wheel is available as a factory-installed option.

With its contemporary styling and free flowing curves, the NSX instrument panel melds authentic refined materials and surface textures and the easy-to-use and ergonomically designed systems that make up the simple sports interface (driver instrumentation and center console), offering intuitive and stress-free operation and functionality.

Visually, both driver and passenger are treated to a clean and minimalist design aesthetic across the entire instrument panel. Uncluttered with easy access to controls for all primary systems, both the instrument panel and center console feature hand-crafted materials including genuine leather atop the instrument panel, Alcantara across the top of the driver's gauge cluster hood, with additional Alcantara trimming for the center console and glovebox. Critical surfaces of the console have been fortified with additional padding for optimal knee and elbow comfort and support.

Front and center of the instrument panel is an 8.0-inch Dynamic Thin-Film Transistor (TFT) gauge cluster, overlaid with a digital analog tachometer dial that gives the appearance of a traditional tachometer. Within the tachometer is the digital speedometer readout and full-color Multi-Information Display (MID). The TFT center meter is flanked by digital gauges displaying the SH-AWD system motors state of charge/assist (left) and battery state of charge (right), with an analog engine coolant temperature gauge on the left and a fuel gauge to the right.

The customizable Multi-Information Display (MID) displays a wide variety of functions and information and is controlled by a thumb dial on the right side of the steering wheel. The MID also incorporates the Acura Maintenance Minder™ system, which alerts the driver of upcoming maintenance needs via the MID. Should a fault occur, specific warning information will appear on the MID.

The driver's center meter is tied into the Integrated Dynamics System to provide a visual compliment to the customizable dynamic and auditory elements of the Acura NSX driving experience.

When driving, as engine speed increases, the outer ring of the tachometer will flash red once the engine speed exceeds 7,000 rpm to alert drivers that they are approaching the 7,500 rpm redline. Also, when a new Integrated Dynamics System mode is selected, the MID displays a graphic representation of Integrated Dynamics System component systems—powertrain, SH-AWD, VSA, suspension and steering.

Once seated, the driver simply depresses the brake pedal and pushes the Start/Stop button located to the right of the steering wheel to start the vehicle. To start the vehicle in accessory mode without engine startup, the driver can press the Start/Stop button without the depressing the brake pedal. At the conclusion of driving, the driver presses the Start/Stop button again to turn the engine and electrical accessories off.

An integral part of the NSX's elegantly simple driver interface, the center console contains the Display Audio touchscreen, Dual-Zone Climate Control, the Integrated Dynamics System control knob, three-position heated seat controls, Electronic Gear Selector, Electronic Parking Brake and two storage compartments.

A 7-inch high-resolution WVGA capacitive Display Audio touchscreen is included as part of the standard equipment package. Access to the audio system controls, telematics and customizable vehicle features is provided through this bright and clear interface.

When the driver first opens the door, the Display Audio touchscreen will illuminate and display a custom NSX animation at vehicle startup. At the conclusion of driving the vehicle, the Display Audio touchscreen, the MID display and instrument lighting will dim progressively into darkness.

Dual-Zone Automatic Climate Control System with Humidity Control and Air Filtration

Every Acura NSX includes a dual-zone automatic climate control system with humidity control and air filtration. The system allows the driver and passenger to pre-select their preferred temperature settings, and then automatically adjusts airflow volume, direction and temperature to maintain a comfortable climate within the vehicle. Push-button defrost helps to clear up fogged or icy windows quickly and conveniently for improved outward visibility.

With its micron air filtration system, the dual-zone automatic climate control system is capable of filtering particulate as small as 0.3 microns. Humidity control further improves the vehicle's interior air quality and driver/passenger comfort levels by using a sensor within the cabin to detect temperature and moisture levels and regulating airflow to maintain a comfortable humidity level.

Located at the base of the instrument panel/center console juncture, the driver can easily reach the large Dynamic Mode dial to make Integrated Dynamics System drive mode changes (Quiet, Sport, Sport+ and Track) without taking their eyes off the road ahead.

The Acura NSX adds the convenience of an Electric Parking Brake (EPB), allowing the driver to engage the parking brake by simply pulling on a rocker switch located on the center console.

The parking brake also includes the convenience of Automatic Brake Hold which once activated, can maintain rear brake hold even after the brake pedal has been released. With the driver's seatbelt on and the vehicle in Drive with a foot on the brake pedal, Automatic Brake Hold can be initiated by pressing the Brake Hold button located near the Electric Parking Brake rocker switch on the center console. A "brake hold" message will appear on the instrument panel to alert the driver that the system is currently activated. The foot can be removed from the brake and the vehicle will remain stationary; pressing down on the throttle pedal will deactivate the brake hold feature and the vehicle will start moving.

The new NSX offers a number of convenient storage areas for both driver and passenger. At the base of the center console is a handy inset console front pocket. An additional storage pocket located along the top of the center console between the seats is designed to accommodate a smart phone.

The center console also includes a roomy rear console storage box that contains a 1.5-amp USB interface port that can sync a smartphone to the Display Audio touchscreen for operation of Apple CarPlay and Android Auto and a phone cord management device located underneath the rubber mat that lines the bottom of the rear storage box.

Additional storage is offered by the glovebox, which also includes a 1.0-amp USB interface port that can be used for audio devices such as MP3 players.

The rear cargo area of the new NSX is pleasantly spacious and versatile for a mid-engine high-performance supercar. With 4.4 cubic feet of space and 100 lbs. of capacity, the NSX trunk can conveniently accommodate weekend luggage for two, or even a golf bag—all easily accessed through the rear cargo area's wide opening. A set of four rear cargo area tie-down anchors are included to help secure items placed in back, and an accessory cargo net for the rear area is also available. The trunk can be opened using the remote key fob, a button located on the driver's interior door or by depressing a discretely located button under the trailing edge of the trunk lid.

A valet lock-out switch is located in the NSX's glovebox. The driver can activate the valet lock-out switch and lock the glovebox to prevent access to the locked rear cargo area.

The exceptional dynamic capabilities of the new Acura NSX are enabled by its revolutionary Sport Hybrid Super Handling All-Wheel Drive power unit, the first such system of its kind in a supercar, utilizing electric motor torque in combination with engine power to enhance every element of dynamic performance—acceleration, handling and braking.

At the heart of this new Sport Hybrid power unit is a bespoke, mid-mounted twin-turbocharged, 75-degree, 3.5-liter DOHC V6 engine with dry sump lubrication, electric Direct Drive Motor, and an all-new 9-speed dual clutch transmission (9DCT). Together, these components comprise the rear power unit. Amplifying the instant responses and dynamic handling performance of the NSX is the front Twin Motor Unit (TMU), with two electric motors independently driving the left and right front wheels.

The NSX's Sport Hybrid power unit offers exceptional horsepower and torque with a broad powerband for tremendous throttle response and acceleration. Peak total system output is 573 horsepower—500 horsepower from the gasoline engine and 73 horsepower from the front TMU and Direct Drive Motor.

By creating a vehicle propulsion system that utilizes both mechanical and hybrid-electric components rather than just a conventional gasoline-powered internal combustion engine, Acura endows the NSX power unit with constant and linear power anywhere in the powerband, at any speed, with virtually zero delay.

For example, at initial launch from a standstill, the front-mounted Twin Motor Unit (TMU) and the Direct Drive Motor immediately supplement power production from the twin-turbocharged V6 engine, using the abundant and instantaneous torque production inherent in electric motors. Conversely, once the vehicle has reached a steady state cruising speed, the twin-turbocharged V6 engine becomes the primary motive force for the vehicle, with the three electric motors providing supplementary power and/or yaw control when necessary.

While the primary focus in the development of the all-new Acura NSX's clean-sheet power unit was all-out performance, efficiency and environmental sustainability are also important characteristics—as with any Acura powertrain. Therefore, the all-new NSX not only boasts a best-in-class EPA combined fuel economy rating of 21 mpg (20 mpg city/22 mpg highway), but it also meets the California Air Resources Board's ultra-low emissions vehicle (ULEV) requirements.

Featuring a wide V-angle of 75 degrees for a low center of gravity, the NSX's 3.5-liter twin-turbo V6 engine achieves the ideal balance between power production, overall compactness and low mass. It combines both direct and port fuel injection, along with Dual Variable Valve Timing Control (VTC) to deliver optimal camshaft phasing, allowing for precision combustion control throughout the entire rpm band while achieving high power output.

Additional key engine design elements include a sand-cast aluminum engine block, lightweight and compact aluminum cylinder heads, plasma transferred wire arc thermal spray-coated cylinder walls (for high thermal efficiency with low weight and compact size) and a dry sump lubrication system that significantly reduces the engine's center of gravity while ensuring consistent engine lubrication under high cornering load conditions.

The NSX utilizes swing arm-type valve actuators which allows for a compact head structure and reduces the inertial weight of the valvetrain by 22 percent compared to a rocker arm-type design. The innovative design was derived from Honda racing engines. Intake and exhaust variable cam timing (VTC) is deployed to provide an excellent balance of high power, torque, fuel efficiency, and emissions.

Developing a bespoke twin-turbo system for the all-new engine was a logical choice, offering a strong balance of high power with considerable torque, high fuel efficiency and low emissions, while also offering inherent packaging advantages. Maximum boost pressure is set at 105 kPa (1.05 bar, or 15.23 psi). High volumetric flow air-to-air intercoolers are adopted, dramatically reducing intake air temperature while simultaneously increasing the density of the air intake charge for maximum power production.

Making use of an electronic wastegate for each turbocharger for fast response and precise control, the single-scroll turbocharger design allows for the use of relatively small turbos to minimize weight and improve packaging while still meeting power and performance benchmarks.

Utilizing an aluminum engine block and heads offered three key advantages compared to traditional cast iron block and head configurations: (1) greatly reduced mass; (2) improved thermal conductivity; and (3) improved heat dissipation. Most aluminum engines require the fitment of cast iron cylinder liners to provide sufficient wear resistance. But engineers on the Acura NSX's power unit development team addressed this issue by employing a plasma transferred wire arc thermal spray to the cylinder walls—a recently developed technique that offers 52 percent better heat transfer (thermal conductivity) with greatly reduced weight versus cast iron liners.

Using a thin-diameter wire as feedstock material (approximately +/-1 mm), the process melts the wire down to an atomized form that can then be sprayed onto the cylinder walls. A supersonic plasma jet formed by a transferred arc between the tip of the wire and a cathode is used to spray the molten material, stacking the tiny particles on top of each other to form a very thin yet extremely wear-resistant coating.

Along with the improved engine efficiency via reduction of internal friction, additional benefits from the thermal spray process include a nearly seven pound decrease in overall engine weight compared to iron cylinder liners, improved wear resistance and reduced oil consumption, and increased horsepower/torque production and throttle response.

Furthermore, thanks to the addition of plasma transferred wire arc thermal spray, additional water channels are able to be placed between the cylinder bores for improved cooling efficiency via better control of coolant flow.

Using engineering and design expertise drawn straight from the company's extensive racing experience, the cylinder heads fitted to the twin-turbo V6 are highly compact and include smaller valvetrain components. This resulted in a notable reduction of inertial weight as well as a 22 percent reduction of cylinder head mass compared to conventional designs. The reduction in mass also helps lower the vehicle's center of gravity.

The cylinder heads utilize a three-piece water jacket for improved cooling efficiency and coolant flow control. Additionally, the race-inspired cylinder head design optimizes the swirling of intake air so that fuel mixes with it in a more ideal manner for improved combustion—thus improving efficiency and emissions performance.

With a compression ratio of 10.0:1 the NSX engine has a specific power output of more than 140 horsepower per liter of engine displacement. The engine safely and reliably achieves the high specific output due to a number of advanced technologies including the efficient twin-turbo system, low internal friction, heat transfer properties of the plasma transferred wire arc thermal spray on the cylinder walls, sodium-filled exhaust valves, implementation of both direct and port injection, and the superior combustibility of fuel from the high-swirl ports.

The NSX engine incorporates proprietary Dual VTC variable valve timing control technology which delivers an excellent balance of high torque and maximum power output with reduced exhaust emissions and superior fuel efficiency.

At engine idle, Dual VTC stabilizes combustion for smooth idling by minimizing intake and exhaust valve overlap, therefore decreasing the amount of exhaust gas recirculation. During steady-state cruise or under light acceleration, the system reduces exhaust emissions and engine pumping losses by optimizing valve overlap. Under wide open throttle at low engine speeds, the overlap of the intake and exhaust cam timing is expanded so that the turbochargers can work at maximum efficiency for optimal power delivery and responsiveness. Conversely, when operating the engine at elevated rpms, overlap of the exhaust and intake timing is minimized for improved volumetric efficiency to create maximum power.

The NSX engine combines both direct and port fuel injection systems to provide outstanding power with exceptional emissions performance.

Direct injection is the primary means of fuel delivery within each cylinder, while port injection is used for additional power output in high-performance driving situations. The direct injection system's electronic fuel injectors are mounted in the cylinder heads and spray a very fine, highly atomized mist of fuel directly into each cylinder under very high pressure so that the fuel ignites almost instantaneously and completely with ignition spark, maximizing engine performance and fuel efficiency with reduced emissions. Under high performance demands, the port injection system supplements the direct injection system, feeding fuel into the intake ports where it mixes with the incoming air for increased power production.

The direct and port injection systems are fed by two specially designed fuel pumps, one feeding the direct injection system at a fuel pressure of 65 psi, the other supplying the port injection system at 51 to 73 psi.

The Acura NSX's engine includes advanced lean-burn combustion technology that allows for homogenous and weak stratified combustion to occur within the cylinder due to ultra-precise control of the fuel injection. By ensuring that fuel spray angle and direction do not interfere with the intake valves, along with a strong air/fuel swirl from the high tumble port, high power output and low emissions are effectively combined. Along with optimized piston head and intake port shapes, the highly accurate fuel spray and injection pattern play pivotal roles in this advanced combustion concept.

A two-into-one intake manifold design minimizes torque deviation between each bank of cylinders. Twin throttle bodies allow more air into the system and finer throttle control while simultaneously reducing the pulsation of air.

Compact and lightweight, the stainless steel exhaust system fitted to the NSX includes two catalytic converters per cylinder bank and four outlets for excellent exhaust gas flow and low emissions. Silicon exhaust system mounts resist heat and offer a robust means of securing the exhaust system to the vehicle, helping to reduce vibration while ensuring system integrity and long life.

To enhance the interior auditory experience, the NSX includes a new Intake Sound Control system that works cooperatively (via the Integrated Dynamics System) with the Active Exhaust Valve system.

Intake Sound Control utilizes a pipe, connected directly to the engine's intake manifold, with an electrically operated butterfly valve that can be opened and shut, depending on the Integrated Dynamics System setting, and a diaphragm that translates high pressure air from the manifold to lower pressure sound waves. On the other side of the diaphragm, the single pipe then splits into two pipes that transmit sound to twin outlets in rear uppermost portions of the cabin. Sound transmission and effect are varied in concert with the four driving modes of the Integrated Dynamics System (Quiet, Sport, Sport+ and Track)—with 25 decibels sound pressure level range between Quiet and Track modes—a tremendous variance in audible sensation.

An Active Exhaust Valve system has been developed for the new NSX that combines quiet and refined driving and pulse-quickening excitement, operating as a complementary component of the Integrated Dynamics System. The system utilizes two distinct exhaust paths controlled by two electrically-operated valves.

In Quiet mode, the exhaust valves are closed and the exhaust gases pass through silencers for a more subdued exhaust sound. Power and torque production from the twin turbo V6 engine is ample.

In Sport mode, the exhaust valves are closed unless driver demand is high enough and then will open.

In Sport+ or Track modes, the Active Exhaust Valve system is open, bypassing the silencers for a full, uninhibited flow of exhaust gases and a full-throated exhaust note.

Together with cabin sound modulation technologies—Active Sound Control and Intake Sound Control—the Active Exhaust Valve system serves to create a customizable auditory experience both within and outside of the NSX—from the hushed silence of Quiet mode to the full concerto of Track mode, when the cabin is filled with sounds every driving enthusiast loves to hear—the high-performance "pop" from the exhaust when executing an upshift; the quick blip of the throttle upon downshifting; and the occasional distinctive off-throttle burble that is a welcome reminder of the power and torque capability of the twin-turbocharged V6 engine.

In another application of race-bred technology, the all-new Acura NSX is the first production Acura vehicle to use a dry sump engine lubrication system. By replacing the engine's conventional oil pan with a separate oil reservoir and a dedicated chain-driven oil pump mounted directly to the lower engine block, the system is designed to prevent oil starvation under high lateral G loads.

After being fed to the engine for lubrication, oil is collected from the lower engine block by six separate scavenger pump impellers and then fed back into the oil tank by a pair of pump rotors.

Importantly, the adoption of a dry sump system allowed designers to mount the engine 2.4 inches (61 mm) lower within the chassis, significantly lowering the center of gravity thanks to the elimination of a traditional oil pan. The more efficiently cooled oil also helps promote maximum engine power output.

As a byproduct of its Sport Hybrid power unit, the NSX utilizes its Direct Drive Motor to start the engine, replacing a conventional 12-volt engine starter motor.

Along with a significant weight savings, further mass reduction was realized by eliminating the 12-volt starter ring gear normally required by a conventional engine starting system.

To help improve fuel efficiency, the NSX comes equipped with idle stop capability. When the system is active and certain operating conditions are met, the NSX engine will automatically shut off when the vehicle comes to a stop. The system is not engaged when Sport+ or Track modes are selected. When stopped, a special cold storage evaporator in the air conditioning system helps maintain a comfortable cabin temperature even in warm weather.

Engine restarts are exceptionally smooth and quick, supported by the use of the powerful Direct Drive Motor as an engine starter. Idle Stop operation is also fully integrated into the operation of the Automatic Brake Hold system.

The NSX power unit development team further improved engine performance and refinement through reduction in experienced noise and vibration. The latest in engine balancing technology and a number of new processes are applied to achieve optimal balance. These include the use of next-generation engine diagnostic equipment to more accurately measure engine imbalance, and the application of variable weight bolts applied to the eight mounting holes in the flywheel, and the addition of nine mounting holes in the crankshaft viscous damper which can be used for fine tuning. Achieving a high degree of harmonic equilibrium not only greatly reduces engine vibration, but also decreases wear of the engine's internal componentry for superior reliability and longevity.

As an important additional quality step prior to fitment within the NSX, the engine undergoes a "hot fire" break-in program, wherein the engine is run under load on a specially designed engine dynamometer for an equivalent of 150 miles of service.

The Acura NSX's bespoke 9-speed dual clutch transmission (9DCT) works in concert with the Rear Direct Drive Motor to make full use of the power unit's broad powerband, producing quick and precise gear changes that support the instant acceleration responses. As a key component of the power unit's packaging, the 9DCT has been optimized for compact size, low mass and low center of gravity.

The 9DCT has a very wide ratio range that allows for optimal gear selection in any driving condition. First gear ratio is configured for maximum vehicle launch acceleration, while the close-ratio gears (2nd through 8th) are matched to make the most of the power unit's powerband. Conversely, high gear (9th) has been optimized for fuel efficiency during steady-state highway cruising. When driving in ninth gear on a level surface at 60 mph, the twin-turbo engine is spinning at only 1,700 rpm.

In efforts toward compactness, the clutches and the differential are uniquely situated side-by-side in a common housing. Also, the parallel shaft layout reduces overhang from the rear axle while the center of mass is moved forward.

One of the key parameters that sets a supercar apart from competing vehicles is how quickly it can execute gear shifts. To deliver superior shifting performance, the 9DCT features unique components to deliver lightning quick yet smooth gear changes.

Highly rigid shift forks composed of a specialized high-strength cast iron play a key role in providing quick shifts. A total of five shift forks are used for the gear actuator system: a one-way clutch is used for 1st gear; four shift forks are used for the 2nd through 9th gears; and a fifth shift fork is employed for Park and Reverse.

Ultra-quick shift response and engagement with reduced weight (vs. conventional pneumatic or hydraulically operated gear actuators) is made possible by the use of a compact electric motor as a gear shift actuator. Weight is reduced by eliminating the high-pressure hydraulic pump that is typically used in a gear shift actuator system, while providing for excellent reliability and system robustness.

Like the aforementioned electric motor-powered gear actuator, the electric clutch actuator eliminates the need for a high-pressure hydraulic pump. Control of the clutch is accomplished via a closed-circuit hydrostatic structure, providing oil pressure on demand with greater efficiency.

Adding to the performance characteristics of the NSX's advanced 9-speed DCT is the ability to modify shift speed and feel via the distinctly different transmission settings within the driving modes of the Integrated Dynamics System:

Quiet - Transmission shift map directs gear shifts at lower engine speeds

Sport - Transmission allows the engine to rev more freely and makes gear changes in a higher RPM range

Sport+ - Accommodates higher engine speed gear changes with quicker, more aggressively executed upshifts and downshifts

Track Mode - Fastest upshifting—40 milliseconds faster than Sport+ settings

To minimize powertrain vibration, the flywheel has been designed to also act as a mass damper to minimize mechanical/harmonic vibration caused by oscillation, while helping to ensure structural integrity and longevity of the transmission case.

The new NSX's remarkably crisp turning capability and tractability is further enhanced by a mechanically-based limited-slip differential (LSD).

Designed to deliver excellent poise and stability while making of the most of the power unit's ample power production, the torque-sensitive multi-plate clutch is lighter and more compact than a similar unit with a helical gear configuration. Also, the multi-plate design allows for improved wheel coupling for smoother and more efficient operation.

The NSX's LSD torque bias ratio—an index for slip limit torque that compares torque shifted from a high rotation axle to a low rotation axle—has been optimized to provide two distinct LSD performance settings ideal for when the wheels are being driven or when the vehicle is coasting.

Engineered to complement the Twin Motor Unit (TMU) and Vehicle Stability Assist (VSA) systems with precision torque vectoring and enhanced traction maintenance, the LSD helps advance vehicle performance in a number of driving situations:

Under Braking/Deceleration Approaching a Turn - Increases engine brake torque on the outside tire/wheel for improved vehicle stability

Straight-line Driving - Torque is transferred left-to-right as necessary for enhanced vehicle stability when driving in a straight line.

Under Acceleration while Turning - Overall vehicle tractability and poise is improved by shifting torque to the outside tire as traction from the inside tire decreases.

By employing strategically-placed rear power unit mounting points—up high at the front of the engine along with a mounting cradle bracket down low at the rear (connected to the transmission)—roll, pitch and yaw motion of the power unit is greatly reduced, providing greater acceleration response and handling ability.

The Sport Hybrid system is a suite of highly advanced components at the center of the hybrid-based systems of the power unit. Each component is engineered to minimize both weight and size in order to reduce overall vehicle mass, and carefully packaged within the NSX to lower and center the mass within the vehicle. Collectively, the Sport Hybrid system includes the Twin Motor Unit (TMU), Direct Drive Motor, Power Drive Unit (PDU), and Intelligent Power Unit (IPU).

The new Acura NSX's instant and linear acceleration coupled with outstanding dynamic capability is enabled in large part by its front-mounted Twin Motor Unit (TMU). Designed to be as small and lightweight as possible while delivering ample torque and power, as well as precise torque vectoring to the front wheels, the TMU is a unique and highly efficient solution to provide supplemental power to the twin-turbo V6 engine for instantaneous acceleration whenever desired.

The TMU provides instant torque as well as AWD capability, allowing direct and immediate acceleration with a heightened sense of G-loading that invigorates the senses. Further, the TMU can dynamically apportion its torque to create a yaw moment, enhancing cornering performance. Finally, the TMU recovers braking energy during deceleration to supply power to the hybrid batteries.

Inside its die-cast aluminum housing are two electric motors positioned back-to-back. Each 36 horsepower motor powers a single front wheel and can also apply negative torque to the same wheel. A gear mechanism allows the motors to decouple and still provide on-demand torque vectoring, helping to improve efficiency in certain conditions.

To achieve maximum acceleration from a standstill and to meet the NSX engineering and design team's target of instant response, the TMU and Direct Drive Motor provides the bulk of the accelerative force during initial acceleration from a standstill. After the first 0.15 seconds/0.1 G off of the line, the high horsepower and torque from the twin-turbocharged V6 engine enters the fray, along with still more power from the Direct Drive Motor. From there, the engine exponentially increases its power contribution as the vehicle continues accelerating.

The TMU is also a key motive force for driving in the Quiet mode setting of the Integrated Dynamics System, allowing for hushed vehicle operation by powering the NSX electrically for short distances.

The Direct Drive Motor, mounted between the engine and transmission, is ideally packaged to provide additional torque and power assist to the rear wheels in the most efficient manner.

To help eliminate the response delay typically associated with turbocharged engines, the Direct Drive Motor (shown at left) acts directly on the engine's crankshaft which, together with the TMU, help the NSX realize immediate, high-output, high-torque acceleration performance. The effectiveness of this design is particularly noticeable in everyday driving when accelerating from a standstill and at low engine speeds. Additionally, the Direct Drive Motor acts as a generator to help charge the hybrid batteries, while also acting as the engine starter.

The Direct Drive Motor is liquid cooled to ensure ample cooling and heat dissipation even when the system is being worked hard, such as on a track day.

Neatly packaged in the cabin, just forward of the rear bulkhead, the Intelligent Power Unit (IPU) acts as the primary heart and brains of the E-Drive system, integrating the lithium-ion battery pack, junction board, a high-voltage distribution bus bar, 12-volt DC-DC converter, electric motor ECU, lithium-ion battery ECU and the ECU for the TMU.

Thanks to the integration of a next-generation lithium-ion battery pack and a caseless structure for key Intelligent Power Unit (IPU) components, the Acura NSX's IPU system is 35 percent smaller and 30 percent lighter than the IPU in the Acura RLX Sport Hybrid sedan.

When driving in Sport, Sport+ and Track modes, the vehicle's air conditioning system is used for supplemental cooling of the IPU for optimal efficiency and performance. During development, the system was tested extensively in the desert heat of Dubai in order to ensure proper function in extreme ambient temperatures.

Packaged within the IPU is the lithium-ion battery pack which stores the electrical energy to power the TMU and Direct Drive Motor.

The high-output battery pack consists of four modules, each with 18 individual battery cells (72 cells in total) contained within a specially designed caseless structure that utilizes the vehicle body itself for a lightweight yet sturdy housing. Compared to the latest Acura RLX hybrid, the NSX battery pack's power density (stored energy per kilogram) has been increased 10 percent while energy density is up 15 percent.

Power output and efficiency of operation have been further improved by implementing a cooperative battery cooling system, fed by fresh cool air channeled into the passenger compartment via the vehicle's air conditioning. Cool air from within the cabin circulates through ducting to cool both the lithium-ion batteries as well as the DC/DC converter.

The Power Drive Unit (PDU) dictates the power management strategy of the Sport Hybrid SH-AWD system, including motor power and battery recharge. The PDU also incorporates three separate converters (converting direct current to alternating current) for use by the power unit's three electric motors: the twin motors of the front-mounted TMU and the Direct Drive Motor. This compact "three-into-one" PDU design is critical to the system's compact packaging and the ability to mount it centrally in the vehicle, in the center tunnel (beneath the center console).

The next-generation NSX chassis, consistent with the Sport Hybrid SH-AWD powertrain and Multi-Material body, combines fundamental concepts in sports car design with advanced new technologies to elevate and enhance the NSX driving experience.

Anchored to the vehicle's ultra-rigid aluminum-intensive space frame and industry-first ablation cast frame nodes, the NSX's sophisticated all-aluminum front and rear suspension systems—augmented by third-generation active magnetorheological (MR) damper technology, dual-pinion variable gear ratio electric power steering (EPS) system, and electro-mechanical sports brakes—elevate the NSX's dynamic capabilities and responses to driver inputs while supporting the breakthrough capabilities of its Sport Hybrid SH-AWD system.

Deceleration capability is enhanced with a next-generation electro-servo braking system that combines the effectiveness of a mechanical (friction) braking system that utilizes large ventilated rotors and aluminum brake calipers with the efficiency of a seamlessly integrated regenerative braking system.

One of the key traits that set the original Acura NSX apart from its contemporaries was its novel use of a finely-tuned aluminum suspension. The NSX team went back to the fundamentals to design the next-generation NSX's lightweight all-aluminum, fully independent front and rear suspension system.

Utilizing lightweight yet rigid aluminum alloy components at all four corners, the NSX's suspension keeps unsprung weight to a minimum while retaining component stiffness for instant and accurate response. Designed to work seamlessly with the advanced electric power steering system, the optimized tuning of the NSX's steering and suspension systems allow for both nimble responses at low speeds, coupled with superlative high-speed stability.

The all-aluminum front suspension has been optimized with compact and lightweight components and suspension geometry developed for superior handling performance, crisp and communicative on-center steering feel and excellent stability. Specifics include:

All-aluminum, forged double wishbone/cast aluminum knuckle design

Double ball joint lower control arm to mitigate torque disturbance from the front Twin-Motor Unit (TMU) torque vectoring

No unwanted steering kickback

Third-generation active MR dampers

Rear Suspension

Featuring lightweight all-aluminum components, the rear suspension employs a sophisticated independent multi-link design. Specifics include:

All-aluminum, forged multi-link/cast aluminum knuckle design

High lateral rigidity

Third-generation active MR dampers

Making use of Acura-tuned third-generation magnetorheological (MR) dampers in place of conventional shock absorbers, the Acura NSX's highly advanced suspension essentially acts as a continuously adaptive "active" system that can adjust damping forces in a fraction of a second, instantaneously adapting to the driving situation, driver inputs and road conditions.

The new third-generation MR damper technology offers the widest range of damping force and the fastest response for maximum handling capability and ride quality in all driving conditions. The reservoir within each of the NSX's MR dampers is filled with a special magnetorheological (MR) fluid that contains microscopic metallic particulate. Running an electric current to each MR damper creates a magnetic field within the fluid that causes an instantaneous change in the fluid properties and resulting change in damping force.

While many active dampers make use of a an internal valve-based technology to vary the damping force, the Acura MR dampers utilize a valve-less design that offers a much broader range of damping force and more rapid response.

The lightning-quick response rate and superior damping properties allow the NSX to make optimum use of a high-performance tire design and low-profile sidewall while still providing comfortable ride quality.

The MR dampers also function as a component of Integrated Dynamics System via two unique damper tuning settings—one biased toward unsprung mass control, used for Quiet and Sport modes; and a second with optimized performance tuning biased toward sprung mass control, used for Sport+ and Track modes.

The Acura NSX chassis design and engineering team has configured a bespoke wheel and tire package that extracts optimal performance from the platform, not only in lateral grip but in every element of driving performance including acceleration and braking.

The standard wheel design package for the new NSX includes lightweight Y-spoke forged aluminum alloy wheels wrapped in Continental Conti-Sport Contact 5P tires (245/35ZR19 front; 305/30ZR20 rear) developed jointly with Continental specifically for the NSX. This tire package strikes an excellent balance between high performance and everyday drivability, offering high levels of traction in both wet and dry conditions.

The unique "Y" wheel design is a result of the NSX engineering team's extensive research to find the strongest and most rigid spoke structure with the least amount of material. Forged in high-strength aluminum, the wheel design offers a lower total weight than any wheels of similar size and material composition within the NSX's competitive class.

An optional factory-installed wheel set utilizes a stylish thin interwoven wheel spoke design featuring a machined/polished, fully polished, or fully painted finish.

Both wheel packages feature staggered fitment to optimize chassis performance, the front wheels measuring 19 x 8.5J, with wider 20 x 11J wheels at the back.

The Acura NSX comes standard with high performance summer tires; ultimate handling performance tires for track day outings are optionally available.

The NSX's sophisticated electric power-assisted rack-and-pinion-based steering system (EPS) responds instantaneously to steering input and automatically adjusts to deliver the appropriate level of power assist in all driving situations, exhibiting many advantages over an engine-driven hydraulic-based steering system:

Reduced weight and improved packaging due to its compactness and fewer components—no hydraulic fluid, pump, fluid storage tank or hydraulic fluid lines/hoses

Reduced levels of noise and vibration without the hydraulic system

Improved fuel efficiency with no parasitic drag from an engine-driven power steering pump